|

|

Winemakers do not often get a vacation. In the winery, there is always something to do. One of those tasks is racking the wine. Kathy and I helped winemaker, David Zuchero, at Tin Lizzie Wineworks rack the wine in seven barrels. It took the three of us about five hours, although I do believe that we were increasing speed throughout the day rather than slowing down.

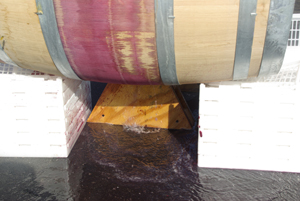

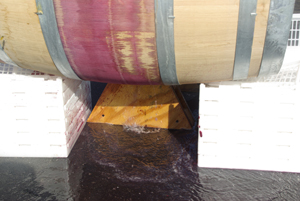

Racking is relatively simple. Moving and lifting the barrels (while empty) was the hardest part. We racked the wine from the first barrel to an empty barrel. While transfering the wine, we kept careful watch for the lees that settled at the bottom of the barrel. We wanted to discard the dead yeast cells. Once empty of wine, we moved the barrel to an outside area to drain the lees and power wash the barrel’s inside. The lees look like a gooey red-purple sludge. The power washing didn’t take long. For the first minute the water that exited the barrel was red-purple in color. It then changed to clear. The head of the power washer rotates while in the barrel blasting water to all parts of the barrel. We washed each barrel for about five minutes. Now the barrel was clean inside and wine could be transferred to it. Racking is relatively simple. Moving and lifting the barrels (while empty) was the hardest part. We racked the wine from the first barrel to an empty barrel. While transfering the wine, we kept careful watch for the lees that settled at the bottom of the barrel. We wanted to discard the dead yeast cells. Once empty of wine, we moved the barrel to an outside area to drain the lees and power wash the barrel’s inside. The lees look like a gooey red-purple sludge. The power washing didn’t take long. For the first minute the water that exited the barrel was red-purple in color. It then changed to clear. The head of the power washer rotates while in the barrel blasting water to all parts of the barrel. We washed each barrel for about five minutes. Now the barrel was clean inside and wine could be transferred to it.

After a couple of barrels, Kathy and I knew what we were doing. Everyone was constrained by the speed of the pump. Although it should have emptied the barrels sooner, it was taken much longer than manufacturer specs. With a larger, faster pump, we would have trimmed an hour or two from our total time. We did seven barrels. I can imagine the hours this task would take for wineries with hundreds of barrels.

While the Cabs are aging in barrels I am experimenting with a carboy of Lake County Cabernet Sauvignon at home. For an oak alternative, I decided to experiment with oak infusion spirals. I bought French heavy toasted and French light toasted spirals. One heavy toasted oak spiral was added to the carboy. I’ll test the wine every weekend since oak infusion spirals work quickly and I do not want to over oak the Cab. My game plan is to use the heavy toast for a few weeks and then switch to the light toast.

After one week of heavy toast one can taste the oak influence. The wine had a dark fruit aroma and taste. Also on the taste there were oak neuances. There were tannins on the finish.

Kathy and I contrasted this wine with the first wine we made from a wine kit. That wine has been in a bottle since August 2008. Although fruity, it had a slight geranium taste and aroma. There were almost no tannins on the finish. As of this moment, I prefer the wine in the carboy.

What does this mean for the future? I believe I’ll make wine from grapes rather than wine kits. The kits are nice from the point of view you can make wine in a couple of months at any time of the year. However, the aroma and taste are more iteresting from wine made from grapes. I wonder how much a lug of Malbec from South America will cost in the Spring?

The last two tasks at Vint Hill Craft Winery were pressing the must and racking to barrels. Both tasks were simple, however they were messy and cleanup probably took longer than the tasks. There was plenty of help to clean up after pressing the California Cab. Using a plastic knife, we had to remove the part that was jambed between the wooden slats of the press basket. The leftover must was compacted and looked like a cake. We had to break the pumace apart and throw it out. The last two tasks at Vint Hill Craft Winery were pressing the must and racking to barrels. Both tasks were simple, however they were messy and cleanup probably took longer than the tasks. There was plenty of help to clean up after pressing the California Cab. Using a plastic knife, we had to remove the part that was jambed between the wooden slats of the press basket. The leftover must was compacted and looked like a cake. We had to break the pumace apart and throw it out.

Then the group hosed down everything. Of course that placed a lot of water on the floor of the winery. I began thinking of the wineries in areas where there are water restrictions. We used a lot of water. Of course the drains were uphill. So brooms and squeegees were used to push the water towards the drain. Then the group hosed down everything. Of course that placed a lot of water on the floor of the winery. I began thinking of the wineries in areas where there are water restrictions. We used a lot of water. Of course the drains were uphill. So brooms and squeegees were used to push the water towards the drain.

A couple days later Kathy and I helped with the clean up after pressing Zinfandel. The Zin was very liquidy and splattered everywhere. So the first thing to water blast was the walls. Then we cleaned the floor and equipment. The only mishap was a burst of water from the hose directed at my face. It was only for a moment and of course everyone saw it but unfortunately no one snapped a photo.

After a few days in a tank we racked our wine into a French oak barrel. We also helped to rack other wines into other barrels. The easy job was to place a wand (a long tube attached to a pump) into the tank. It could rest on the side of the tank until the wine was near the bottom, then you would have to hold in closer to the bottom. It didn’t take long to fill a barrel.

After some of the wine is in the barrel we placed Tan‘Cor, Tan‘Cor Grand Cru and Quertanin to the wine in the barrel. We then added more wine to the barrel. Tan’Cor is suppose to improve the overall structure of the wine and to help protect the wine from oxidation during aging. The Tan’Cor Grand Cru also helps with the wine’s structure while enhancing a softer middle palate. It also helps enhance the Cabernet Sauvignon fruit character. The Quertanin helps with wood neuances without the toast and smoke character. These three additions to the barrel sort of jump starts the aging process.

Filling the barrel to the top was easier said than done. I wonder how many gallons were spilled onto the sides of the barrels and the floor. However, we all had accidents with filling barrels including DJ, the winemaker. I knew when the wine reached the top of the barrel but wasn’t fast enough with the turn off valve on the wand. Kathy did the best job of filling barrels without spilling as much wine. It was fun filling a barrel. I was sent to the lab to get more batches of the three aging tannins. My lab skills are improving.

View a short slide show of the racking process.

Pressing the must was a breeze using Vint Hill’s neumatic press. Cleaning up took longer than pressing. Using the forklift, DJ lifted a fermentation bin and dumped the must into the wooden slat press unit. This unit was then rolled under the neumatic press and the pressing began. At first the free run juice came out. The juice was pumped into a stainless tank. More pressure was increased and more wine flowed. The pressing was automatic. Set the pressure on the gauge and let the machine do the work. We were pressing two Cabs from California. One was the Cab that we are making.

After pressing and cleanup we tasted the two cabs from their tanks. Although made from the same sourced grapes on the same day, both Cabs already tasted different. The difference was in part due to different yeasts used in fermentation. The wine will remain in the tanks for a few days during which time heavier particles can settle to the bottom.

Kathy and I helped with another press a couple days later. This time we were pressing California Zinfandel. The Zinfandel must was quite liquidy and splattered during pressing. It did not require the same amout of pressure as did the Cab. Clean up took a bit longer though.

View the short slideshow of the Cab press.

An interesting question was asked yesterday. When does a winemaker’s creativity begin? Given the premise that wine is made in the vineyard, does a winemaker make a difference. Two wines made from the same rows of grapes from the same vineyard having the same data (brix, pH, TA), can end up totally different depending on what the winemaker does.

Perhaps a winemaker’s creativity begins with his first decision. A winemaker has many decisions to make before the bottle of wine is ready to be consumed. Many of these decisions will impact the aroma, taste and finish of the wine. One such decision is the yeast to use in the fermenter. I had to make this decision earlier this fall. My wine used NT50 yeast. My decision was based on what I researched about this yeast compared to the others we could use. I liked the manufacturer’s claims that it “produces well-rounded red wines with structured tannins and good color stability.” Another group using the same grapes from the same vineyards used a different yeast. Right befor racking into barrels we tasted the two wines. They were different. Choosing the yeast is just one of the decisions that may make a difference in the taste of the finished wine.

As I learn about all the things a winemaker can do to the wine, I am amazed and certainly see the impact on the final product. Perhaps the winemaker should be added to the list of elements known as terroir.

While at Tin Lizzie this past weekend pressing grape must, it occurred to me that it may be possible to make jelly from the must. My query received a few raised eyebrows. There is the obvious concern that the juice after fermentation is wine and has alcohol as well as potential yeast cells and bacteria. Then there is the concern that the pectin from the grapes has already been broken down. Pectin is needed to get the jelly to set. Then what should be done about acid. The must had a pH of 3.4 that was rather acetic for wine.

Not deterred I forged ahead. One bucket of must and some kitchen items were all that Kathy and I needed to make our first batch. We placed the must in a sieve lined with cheesecloth. The first and second batches of jelly were made from juice that was free run. Kathy needed to squeeze the cheesecloth holding the must to press out enough juice for the third batch.

We began to boil the juice that was now wine. We added lemon juice and Sure Jell. The lemon juice would assure that there was enough acid and the Sure Jell should add enough pectin to cause the jelly to set. Slowly we added the sugar and brought the mixture to a full rolling boil. During the boiling process any yeast cells would die since yeast cannot survive above 104º F. At 172º F the alcohol began to evaporate. Boiling at 212º should have killed off anything that shouln’t be in jelly and evaporate the alcohol. After ladling into Mason jars we waited to see if the jelly would set. It didn’t take long.

How did it taste? It was delicious. It had a wine nose and taste with a fresh fruit taste. Although dark purple in the jar it was a bit more translucent with some red color when spread out. We returned to Tin Lizzie on Monday where Dave and Randy became official tasters. They liked the jelly. So it is possible to make jelly from fermented must. Now I wonder if different grape musts will produce different tasting jellies.

I put the recipe for Wine Jelly from Fermented Must on the Wine Trail traveler site. Early research indicates that this may be the only recipe for making jelly out of fermented must on the Internet.

A week after crushing the grapes and adding yeast to the must, it was time to press the mixture. The liquid is now wine. In order to extract more wine from the must, rice hulls were added to the must and stirred. Buckets were used to transfer the must from the fermentation bin to the bladder press. At first there was a lot of free run wine. This was the wine that went through the press without pressing. Everyone was surprised at how good the free run wine tasted.

Eventually the fermentation bin was empty and and the bladder was inflated. More juice ran from the bladder. As the juice ran, buckets of the wine were collected and poured into a barrel. The barrel was soon filled; extra wine was poured into a stainless steel tank. The barrel was moved into the barrel room where malolactic fermentation will take place and the wine will age for months.

A ninety-second video shows the process.

We destemmed and crushed our Cabernet Sauvignon at Tin Lizzie Wineworks today. Kathy and I are making a quarter barrel. Actually it is a full barrel of which we will receive a quarter of the bottled wine. The grapes were from Stagecoach Vineyards in Napa. There was talk about this Cab being an after the storm Cab. The grapes were harvested and sorted after the multi-inch rains that pounded the Napa Valley on October 13th. We destemmed 18 lugs of Cabernet Sauvignon and two lugs of Merlot also from Stagecoach Vineyards. The Merlot was harvested prior to the storm and kept refrigerated. We destemmed and crushed our Cabernet Sauvignon at Tin Lizzie Wineworks today. Kathy and I are making a quarter barrel. Actually it is a full barrel of which we will receive a quarter of the bottled wine. The grapes were from Stagecoach Vineyards in Napa. There was talk about this Cab being an after the storm Cab. The grapes were harvested and sorted after the multi-inch rains that pounded the Napa Valley on October 13th. We destemmed 18 lugs of Cabernet Sauvignon and two lugs of Merlot also from Stagecoach Vineyards. The Merlot was harvested prior to the storm and kept refrigerated.

Both grapes were in excellent condition. After the must was in the fermenter, Dave Zuchero had our group conduct tests and add mixtures to the must. We were asked to select a yeast. I suggested that we use Lalvin ICV D21 or Lalvin ICV D80. Our group chose the D80 in part because of the manufacturer’s claim of an intense, fine grain tannin sensation. We like tannins! Dave had one of the group members measure out a yeast nutrient and add to warm water. Next he measured the yeast and added to the water once the temperature dropped to 105º.

Our next tests were to determine the brix levels. I stirred, actually punched down, the must. We gathered some of the juice and measured the brix using a refractrometer. The brix level was at 24. An independent test done by an independent company had the brix of the Cab slightly higher. However the brix of the Merlot was lower. Adding the two lugs of Merlot could account for our slightly lower reading. Our next tests were to determine the brix levels. I stirred, actually punched down, the must. We gathered some of the juice and measured the brix using a refractrometer. The brix level was at 24. An independent test done by an independent company had the brix of the Cab slightly higher. However the brix of the Merlot was lower. Adding the two lugs of Merlot could account for our slightly lower reading.

Dave then placed a probe into some of the juice and recorded the pH level of 3.75. He then had one of the group members add about 500 ml of tartaric acid to the must. Dave did the calculations and pointed out that he will add tartaric acid a little at a time, then take a reading after each addition and add more if needed. Dave will also calculate the TA later. Meanwhile some of the must was added to the pail containing the yeast. We wanted to gradually lower the temperature of the yeast to that of the must. We then added the yeast to the must.

After waiting for the grapes to arive from Stagecoach Vineyards in California via New Jersey it was time for the vintners to process their grapes. The first group destemmed Syrah. They were interested in making a bold Syrah. The grapes were in excellent condition having been presorted at the vineyard. The grapes in plastic lugs were dumped onto a sorting table where few MOG were removed. The MOG consisted primarily of leaves, grape tendrils and a rare piece of a vine. Although bees were plentiful, they managed to fly off prior to destemming.

The must was punched down and samples of juice were collected to read the brix level. Dave used a refractrometer to read the brix while Rob used a hydrometer to determine the potential alcohol levels. The group decided on which yeast to use and began mixing the yeast in a bucket. Juice from the fermentation bin was added to the bucket of yeast. This was done to slowly match the temperature of the yeast with the temperature of the must.

Dave instructed the group about acid levels and had them take the pH reading. The reading was 3.72 and Dave intrepreted that reading and discussed how it would change over the different fermentations. View the one-minute video showing the process.

|

|

Racking is relatively simple. Moving and lifting the barrels (while empty) was the hardest part. We racked the wine from the first barrel to an empty barrel. While transfering the wine, we kept careful watch for the lees that settled at the bottom of the barrel. We wanted to discard the dead yeast cells. Once empty of wine, we moved the barrel to an outside area to drain the lees and power wash the barrel’s inside. The lees look like a gooey red-purple sludge. The power washing didn’t take long. For the first minute the water that exited the barrel was red-purple in color. It then changed to clear. The head of the power washer rotates while in the barrel blasting water to all parts of the barrel. We washed each barrel for about five minutes. Now the barrel was clean inside and wine could be transferred to it.

Racking is relatively simple. Moving and lifting the barrels (while empty) was the hardest part. We racked the wine from the first barrel to an empty barrel. While transfering the wine, we kept careful watch for the lees that settled at the bottom of the barrel. We wanted to discard the dead yeast cells. Once empty of wine, we moved the barrel to an outside area to drain the lees and power wash the barrel’s inside. The lees look like a gooey red-purple sludge. The power washing didn’t take long. For the first minute the water that exited the barrel was red-purple in color. It then changed to clear. The head of the power washer rotates while in the barrel blasting water to all parts of the barrel. We washed each barrel for about five minutes. Now the barrel was clean inside and wine could be transferred to it. The last two tasks at Vint Hill Craft Winery were pressing the must and racking to barrels. Both tasks were simple, however they were messy and cleanup probably took longer than the tasks. There was plenty of help to clean up after pressing the California Cab. Using a plastic knife, we had to remove the part that was jambed between the wooden slats of the press basket. The leftover must was compacted and looked like a cake. We had to break the pumace apart and throw it out.

The last two tasks at Vint Hill Craft Winery were pressing the must and racking to barrels. Both tasks were simple, however they were messy and cleanup probably took longer than the tasks. There was plenty of help to clean up after pressing the California Cab. Using a plastic knife, we had to remove the part that was jambed between the wooden slats of the press basket. The leftover must was compacted and looked like a cake. We had to break the pumace apart and throw it out. Then the group hosed down everything. Of course that placed a lot of water on the floor of the winery. I began thinking of the wineries in areas where there are water restrictions. We used a lot of water. Of course the drains were uphill. So brooms and squeegees were used to push the water towards the drain.

Then the group hosed down everything. Of course that placed a lot of water on the floor of the winery. I began thinking of the wineries in areas where there are water restrictions. We used a lot of water. Of course the drains were uphill. So brooms and squeegees were used to push the water towards the drain. We destemmed and crushed our Cabernet Sauvignon at Tin Lizzie Wineworks today. Kathy and I are making a quarter barrel. Actually it is a full barrel of which we will receive a quarter of the bottled wine. The grapes were from Stagecoach Vineyards in Napa. There was talk about this Cab being an after the storm Cab. The grapes were harvested and sorted after the multi-inch rains that pounded the Napa Valley on October 13th. We destemmed 18 lugs of Cabernet Sauvignon and two lugs of Merlot also from Stagecoach Vineyards. The Merlot was harvested prior to the storm and kept refrigerated.

We destemmed and crushed our Cabernet Sauvignon at Tin Lizzie Wineworks today. Kathy and I are making a quarter barrel. Actually it is a full barrel of which we will receive a quarter of the bottled wine. The grapes were from Stagecoach Vineyards in Napa. There was talk about this Cab being an after the storm Cab. The grapes were harvested and sorted after the multi-inch rains that pounded the Napa Valley on October 13th. We destemmed 18 lugs of Cabernet Sauvignon and two lugs of Merlot also from Stagecoach Vineyards. The Merlot was harvested prior to the storm and kept refrigerated. Our next tests were to determine the brix levels. I stirred, actually punched down, the must. We gathered some of the juice and measured the brix using a refractrometer. The brix level was at 24. An independent test done by an independent company had the brix of the Cab slightly higher. However the brix of the Merlot was lower. Adding the two lugs of Merlot could account for our slightly lower reading.

Our next tests were to determine the brix levels. I stirred, actually punched down, the must. We gathered some of the juice and measured the brix using a refractrometer. The brix level was at 24. An independent test done by an independent company had the brix of the Cab slightly higher. However the brix of the Merlot was lower. Adding the two lugs of Merlot could account for our slightly lower reading.