|

|

With nighttime temperatures in the teens and daytime temperatures struggling to reach thirty, I thought it might take awhile for the blueberries we crushed last week to ferment. Not so. The must went from 16 brix to zero in two days. Dave added more sugar and raised the brix level to eight. When we pressed it over the weekend it was back to zero. I assume that if the original measure was 16 and that was fermented to zero, then increased to eight the total brix would be around 24. That should give us a dry wine around 13+ alcohol. Let me know if my math is off. With nighttime temperatures in the teens and daytime temperatures struggling to reach thirty, I thought it might take awhile for the blueberries we crushed last week to ferment. Not so. The must went from 16 brix to zero in two days. Dave added more sugar and raised the brix level to eight. When we pressed it over the weekend it was back to zero. I assume that if the original measure was 16 and that was fermented to zero, then increased to eight the total brix would be around 24. That should give us a dry wine around 13+ alcohol. Let me know if my math is off.

Pressing started off rather typical. We used stainless steel buckets to transfer the must from the fermentor to the crusher. The volumne of the must was around 400 liters. Dave didn’t have a spare stainless steel tank, so we placed the wine in four 15-gallon demijohns. The first couple of demijohns were free run juice. A taste indicated that the wine was tart with a blueberry taste and aroma. That tartness will be addressed later. We had no problem filling the other two demijohns and began to fill a 2.5-gallon carboy for topping off. We needed another quart of wine and after inspecting the pumice and noting it was still rather moist, it was decided to press again.

During the original press, there were a few leaks as wine shot out from the press in a few spots. Brian came up with an idea of placing plastic bags around the outside of the press. This caught the wine and allowed it to flow to the bottom of the press. The plastic bags worked quite well until . . . During the original press, there were a few leaks as wine shot out from the press in a few spots. Brian came up with an idea of placing plastic bags around the outside of the press. This caught the wine and allowed it to flow to the bottom of the press. The plastic bags worked quite well until . . .

We were filling the carboy when there was a pop and then a shower of blueberry pumice hit Rob and me as well as the sidewall and a bit of the ceiling. The blow out is an example of why one does not wear their Sunday best clothes to a winery to work. Rob definitely had the worst of the splatter. I on the other hand had to be at church in twenty minutes and decided that it would be a good idea to get cleaned up. Besides, even though I wore a hat, some of the pumice and wine managed to make its way to my hair and down my neck.

Dave said it was only about the fourth time in two years that the press had a blowout. I’m sure we will find some humor in this. I did get cleaned up and clothes were washed. My Detroit Tiger hat, although covered in blueberries, cleaned up well. In fact it is cleaner now than it had been in several years. I have already heard comments from my children such as, “You need to wear a hazmat suit when pressing.” Another comment I expect to hear frequently is, “Making blueberry wine is a blast.”

2009 was a year of learning about winemaking. Washington State University offers online courses in winemaking and I took the beginning course. Although I began the course in the spring, I quickly put it off to the fall when the winemaking processes the instructor talked about could be seen in practice at Vint Hill Craft Winery in Virginia and Tin Lizzie Wineworks in Maryland. In addition to a barrel of Cab at each of those wineries, I have a carboy of Cab at home. I was also happy with a batch of dry mead I made. I started the mead in 2008 and bottled it during the summer of 2009. So what are my 2010 winemaking resolutions?

1. Bottle a Cab/Tannat blend. This will be an east meets west wine: Virginia Tannat and California Cabernet Sauvignon.

2. Bottle the Cab at Tin Lizzie Wineworks.

3. Determine if the barrel of Cab at Vint Hill Craft Winery should be bottled during 2010 or if additional aging will benefit the wine.

4. Make a raspberry/mead melomel.

5. Perhaps make a Sauvignon Blanc that is fruit forward with tropical fruit aromas and tastes.

6. Kathy wants to make a peach wine. One of my all-time favorite fruit wines was a dry peach wine.

What are some of your winemaking New Year’s resolutions for 2010?

The final class lesson looked at red winemaking. This rather lengthy class reviewed many of the previously presented winemaking practices as well as highlighted new practices. The lecture began with fermentation. Red wines ferment at warm temperatures. Oxidation is usually not a problem since the skins and seeds form a cap above the fermenting juice. Various methods of mixing this cap with the juice were discussed including punch down, pump over rotary fermentors and pulsed air.

The practices of cold soaking, thermovinification and extended maceration were discussed. It is interesting to note that the instructor pointed out that the benefits of cold soaking are not supported by the current research. On a side note, I’m glad I didn’t spend an extra $500 to cold soak my Cabernet Sauvignon grapes. The instructor discussed adding enzymes to the fermentation and the practice of carbonic maceration.

After fermentation, the must is pressed. Barrel aging and oak alternatives were presented. The instructor talked about oxidation of red wines and the time to be careful about oxidation.

In the previous lesson, the instructor discussed wine styles using the French regions of Burgandy and Bordeaux. In this lesson he also discussed red wine styles and the French regions of Burgandy, Bordeaux and the Rhône.

I often hear that wine is made in the vineyard. But the style of wine is made by the winemaker. There are so many different ways of making wine and so many decisions to make that perhaps winemakers should be given more credit to making the finished wine.

This lesson looked at specific wine making techniques as they relate to white wine. The instructor discussed the importance of cool fermentation and the need to protect the wine from oxidation. The practice of adding enzymes was presented. These enzymes improve juice yield and help in clarification. The comparison between barrel fermentation and tank fermentation was made. The instructor also discussed when and how to stop fermentation depend on if the wine is to be dry or sweet.

The different styles of white wine were presented with white wines from Burgandy and Bordeaux cited as examples. The instructor divides white wines into three styles: dry white wines, full bodied wood aged white wines and aromatic white wines that can be dry or sweet. White Burgundies were discussed in terms of geography, technique of making the wines and taste profile. This was contrasted with white Chablis that has a different taste profile and technique to make them. White Bordeaux wines such as Sauvignon Blanc and Semillon were contrasted.

The instructor chose France for examples of styles and techniques. Other wine regions throughout the world could also have been used. Emphasis was placed on making wines from grapes that do well in your region. It is also important to make wine in a style that differentiates your product from others in your region.

Twice this year we’ve come across a winery that had cases of bottled wine that had a buildup of CO2 in some of the bottles. At a Texas winery there were only a few bottles detected, however the winemaker didn’t want to take any chances and decided to open all the bottles, dump the wine into a tank and rebottle. This same technique was also used at Tin Lizzie Wineworks and we helped with the process that was rather quick.

I for one like a little fizz in my wine, just enough effervescence to tickle the tongue. But others do not especially if it is unexpected. So we tackled several cases of wine that may have had a CO2 build-up. Some of the bottles had some CO2 while others did not, but it was decided to dump the entire batch and rebottle. The process went quickly: sanitize the top of the bottle, remove the cork, pour the contents into a stainless steel barrel (this allows the CO2 to escape), sanitize the inside of the bottle and place on a bottle tree to dry.

We left before rebottling took place. I wonder how often this occurs at wineries. With small batches of wine it doesn’t seem to be an issue. However with large volumns of wine at large wineries, a million bottles or so would certainly challenge arms and wrists.

Eight hundred pounds of blueberries is a lot of fruit. So what can be done on short notice? One option is to make wine. The flats were loaded onto a truck and delivered to Tin Lizzie Wineworks early on the last Sunday of the year. We arrived at 10:00 AM and began to open the containers and dump the fruit into a crusher. With several people working, the entire crush went quickly. When finished we had about 350 liters of blueberry must. Eight hundred pounds of blueberries is a lot of fruit. So what can be done on short notice? One option is to make wine. The flats were loaded onto a truck and delivered to Tin Lizzie Wineworks early on the last Sunday of the year. We arrived at 10:00 AM and began to open the containers and dump the fruit into a crusher. With several people working, the entire crush went quickly. When finished we had about 350 liters of blueberry must.

The must was the consistency of a milk shake. Trying to get a hydrometer reading would be difficult. Dave Zuchero, winemaker at Tin Lizzie, opted for the refractrometer to get an idea of the brix level. The must measured 12 brix on the refractrometer. Sugar would need to be added to raise the brix level and potential alcohol. This was not unexpected. The pH level was 3.37. So there was a good acid level to the fruit. This was also expected.

I did some research on blueberry winemaking before going to Tin Lizzie. Every recipe I found called for the addition of water to the blueberries. Often 15 pounds of blueberries for five gallons of wine was mentioned in the recipes. Dave contacted one of his professors at UC Davis who said treat the blueberries as though they were Cabernet Sauvignon and you don’t have to add any water. Dave decided to add a few gallons of water along with thirty pounds of sugar to the must. He has a good eye for how full the fermenter needs to be in order to fill a barrel. I did some research on blueberry winemaking before going to Tin Lizzie. Every recipe I found called for the addition of water to the blueberries. Often 15 pounds of blueberries for five gallons of wine was mentioned in the recipes. Dave contacted one of his professors at UC Davis who said treat the blueberries as though they were Cabernet Sauvignon and you don’t have to add any water. Dave decided to add a few gallons of water along with thirty pounds of sugar to the must. He has a good eye for how full the fermenter needs to be in order to fill a barrel.

Not that he is going to put the blueberry wine in a barrel. That is just one of the options Dave is considering. When we left, he was considering putting the wine in stainless steel tank and experimenting with oak chips and sugar levels in carboys. One can do a lot with blueberries and there are many different styles to explore.

Kathy and I took our daughter Erin with us to Tin Lizzie. Erin ocassionally writes for Wine Trail Traveler. Being in the country with wonderful people who have a passion for wine is just the right perscription for those who live in New York City and need some relief. Erin’s next stop is Los Angeles and we hope her acting career will afford her some time to visit the California wine regions. Meanwhile, we’ll save a bottle of blueberry wine for her. It is always exciting to have a bottle of wine that you helped to make.

Barreling, clarification, blending and bottling were the topics explored in this lesson. It began with a discussion of barrels and differences between French, American and Hungarian barrels. The instructor talked about the characters that barrel aging could add to wine as well as the degree of toast and a barrel’s lifespan.

Clarification of wine was presented with mentioning it was a slow process, however certain items such as bentonite can be added to clarify wine. Some wineries that have the funds may use centrifuges. Racking will also help with clarification of the wine. The instructor discussed the chemistry behind fining agents, and in addition to the bentonite he discussed polyvinyl-polypyrrolidone, agar and gum arabic, activated carbon and copper sulfate. The practice of cold stabilization was also presented as a means of clarification. Filtration was then discussed.

The practice of blending was presented. It is as much of an art as a science. There was certainly an emphasis of the need to conduct trial blends and collect some quantitative data.

Labeling regulations for wine bottles was presented. Such words as vintage, AVA and vineyard designation require a certain percentage of a particular grape from a particular location to be in the bottle.

The next part of the lesson was about sensory evaluation. It seemed to be somewhat out of place and would have made a nice lesson by itself if expanded. It actually goes hand in hand with blending. The wine aroma wheel was presented as well as different ways to evaluate wine. Once again there was an emphasis on collecting quantifiable data.

The final part of the class dealt with bottling and enclosures. Although there was a certain amount of science and math in this lesson, the general public could benefit from many of the concepts presented.

The fourth lesson explored secondary fermentation. The lecture described in detail the conversion of malic acid to lactic acid. This malolactic conversion is going to affect the pH and TA levels. The lactic acid is less acedic than the malic acid. The secondary fermentation can stabilize the wine and change the flavor.

Some winemakers inoculate with ML strain rather than relying on native ML strain to begin the process. There is some debate on when to begin malolactic fermentation. There are those who argue that primary and secondary fermentations should be separate so that yeast and ML bacteria do not inhibit each other. However some winemakers have done studies on their own and concluded that this in practice is not the case. There are new stains of yeasts that can tolorate a malolatic fermentation going on at the same time. Perhaps when secondary fermentation is started is more of a winemaker’s style.

The flavor of the wine will change after secondary fermentation. Hopefully the wine will become less sour. Usually red wines undergo the malolatic fermentation. White wines depend on the variety and desired end product. Secondary fermentation can produce a buttery component which may be desireable in a Chardonnay, but not wanted in a tropical fruit forward Sauvignon Blanc.

Most people do not have access to must or the leftover pumace after a pressing. We successfully made wine jelly from must. However, if you do not have access to the must what can you do? Most people do not have access to must or the leftover pumace after a pressing. We successfully made wine jelly from must. However, if you do not have access to the must what can you do?

One of the easiest jellies to make is wine jelly. Just pick up two bottles of your favorite wine. If you are planning to make the jelly and use as a gift, pick up two bottles of the recipient’s favorite wine. You will need two bottles because the recipe calls for 3½ cups of wine. You will only get slightly over 3 cups from a 750 ml bottle of wine. I assume you won’t have any problems with the leftover wine, however if you need inspiration the Wine Trail Traveler site has over 130 recipes with wine as an ingredient.

Next collect the materials that you will need. For the recipe you will need wine, lemon juice (I used concentrate and it worked each time), SureJell (I only use this brand of pectin and it worked well) and sugar. That’s it. Now for equipment you will need six one-cup Mason jars or three pint Mason jars. You may have a little left over that you can place in any container and enjoy after it sets. You will need a saucepan large enough to boil the Mason jars before placing the jelly in them. Then this pan will be used for a hot water bath after the jars are filled and sealed. You will also need a saucepan for boiling the jelly. Once the sugar is added, the mixture will foam and if your pan is too small it will boil over and out. I used a five-quart saucepan and had to hold my breath for several seconds, hoping it would not go over the rim. It would be better to use at least a six-quart saucepan.

This is a simple recipe for making wine jelly. Wine jelly not only tastes good, but makes a good gift at any time of the year.

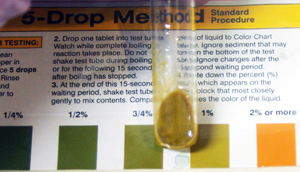

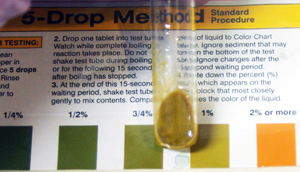

While racking, I ran a sugar test and pH on the wine. Running the sugar test reminded me of high school chemistry class when we used pH paper to match a substance to a color chart with 14 indicators. The sugar test kit that many winemakers use is the Clinitest Reagent Tablets for Urine Sugar Testing. Why reinvent the wheel? If there is already something on the market that does what you want, use it. The process is the same for wine. We were sure that the sugar levels were between zero percent and two percent so we used the five-drop test. Five drops of wine were placed in a test tube followed by ten drops of distilled water. A reagent tablet was added to the test tube. After fizzing you wait for fifteen seconds, then match the color in the test tube with the color on a chart. This gives a reading of the sugar level in the wine. The wines we tested were between zero and two percent risudual sugar. Fermentation will continue to take place while in the barrel. While racking, I ran a sugar test and pH on the wine. Running the sugar test reminded me of high school chemistry class when we used pH paper to match a substance to a color chart with 14 indicators. The sugar test kit that many winemakers use is the Clinitest Reagent Tablets for Urine Sugar Testing. Why reinvent the wheel? If there is already something on the market that does what you want, use it. The process is the same for wine. We were sure that the sugar levels were between zero percent and two percent so we used the five-drop test. Five drops of wine were placed in a test tube followed by ten drops of distilled water. A reagent tablet was added to the test tube. After fizzing you wait for fifteen seconds, then match the color in the test tube with the color on a chart. This gives a reading of the sugar level in the wine. The wines we tested were between zero and two percent risudual sugar. Fermentation will continue to take place while in the barrel.

To determine the pH, I placed a probe into the wine. The probe was connected to an Oakton pH meter. It only took about a minute to get a reading. To determine the pH, I placed a probe into the wine. The probe was connected to an Oakton pH meter. It only took about a minute to get a reading.

Why was this data important? It lets the winemaker know that since there is still sugar in the wine, the wine will continue to ferment. The pH was in the desired range so no additions need to be made at this time. Throughout the aging process, data will be collected and analyzed.

|

|

With nighttime temperatures in the teens and daytime temperatures struggling to reach thirty, I thought it might take awhile for the blueberries we crushed last week to ferment. Not so. The must went from 16 brix to zero in two days. Dave added more sugar and raised the brix level to eight. When we pressed it over the weekend it was back to zero. I assume that if the original measure was 16 and that was fermented to zero, then increased to eight the total brix would be around 24. That should give us a dry wine around 13+ alcohol. Let me know if my math is off.

With nighttime temperatures in the teens and daytime temperatures struggling to reach thirty, I thought it might take awhile for the blueberries we crushed last week to ferment. Not so. The must went from 16 brix to zero in two days. Dave added more sugar and raised the brix level to eight. When we pressed it over the weekend it was back to zero. I assume that if the original measure was 16 and that was fermented to zero, then increased to eight the total brix would be around 24. That should give us a dry wine around 13+ alcohol. Let me know if my math is off. During the original press, there were a few leaks as wine shot out from the press in a few spots. Brian came up with an idea of placing plastic bags around the outside of the press. This caught the wine and allowed it to flow to the bottom of the press. The plastic bags worked quite well until . . .

During the original press, there were a few leaks as wine shot out from the press in a few spots. Brian came up with an idea of placing plastic bags around the outside of the press. This caught the wine and allowed it to flow to the bottom of the press. The plastic bags worked quite well until . . . Eight hundred pounds of blueberries is a lot of fruit. So what can be done on short notice? One option is to make wine. The flats were loaded onto a truck and delivered to Tin Lizzie Wineworks early on the last Sunday of the year. We arrived at 10:00 AM and began to open the containers and dump the fruit into a crusher. With several people working, the entire crush went quickly. When finished we had about 350 liters of blueberry must.

Eight hundred pounds of blueberries is a lot of fruit. So what can be done on short notice? One option is to make wine. The flats were loaded onto a truck and delivered to Tin Lizzie Wineworks early on the last Sunday of the year. We arrived at 10:00 AM and began to open the containers and dump the fruit into a crusher. With several people working, the entire crush went quickly. When finished we had about 350 liters of blueberry must. I did some research on blueberry winemaking before going to Tin Lizzie. Every recipe I found called for the addition of water to the blueberries. Often 15 pounds of blueberries for five gallons of wine was mentioned in the recipes. Dave contacted one of his professors at UC Davis who said treat the blueberries as though they were Cabernet Sauvignon and you don’t have to add any water. Dave decided to add a few gallons of water along with thirty pounds of sugar to the must. He has a good eye for how full the fermenter needs to be in order to fill a barrel.

I did some research on blueberry winemaking before going to Tin Lizzie. Every recipe I found called for the addition of water to the blueberries. Often 15 pounds of blueberries for five gallons of wine was mentioned in the recipes. Dave contacted one of his professors at UC Davis who said treat the blueberries as though they were Cabernet Sauvignon and you don’t have to add any water. Dave decided to add a few gallons of water along with thirty pounds of sugar to the must. He has a good eye for how full the fermenter needs to be in order to fill a barrel. Most people do not have access to must or the leftover pumace after a pressing. We successfully made wine jelly from must. However, if you do not have access to the must what can you do?

Most people do not have access to must or the leftover pumace after a pressing. We successfully made wine jelly from must. However, if you do not have access to the must what can you do? While racking, I ran a sugar test and pH on the wine. Running the sugar test reminded me of high school chemistry class when we used pH paper to match a substance to a color chart with 14 indicators. The sugar test kit that many winemakers use is the Clinitest Reagent Tablets for Urine Sugar Testing. Why reinvent the wheel? If there is already something on the market that does what you want, use it. The process is the same for wine. We were sure that the sugar levels were between zero percent and two percent so we used the five-drop test. Five drops of wine were placed in a test tube followed by ten drops of distilled water. A reagent tablet was added to the test tube. After fizzing you wait for fifteen seconds, then match the color in the test tube with the color on a chart. This gives a reading of the sugar level in the wine. The wines we tested were between zero and two percent risudual sugar. Fermentation will continue to take place while in the barrel.

While racking, I ran a sugar test and pH on the wine. Running the sugar test reminded me of high school chemistry class when we used pH paper to match a substance to a color chart with 14 indicators. The sugar test kit that many winemakers use is the Clinitest Reagent Tablets for Urine Sugar Testing. Why reinvent the wheel? If there is already something on the market that does what you want, use it. The process is the same for wine. We were sure that the sugar levels were between zero percent and two percent so we used the five-drop test. Five drops of wine were placed in a test tube followed by ten drops of distilled water. A reagent tablet was added to the test tube. After fizzing you wait for fifteen seconds, then match the color in the test tube with the color on a chart. This gives a reading of the sugar level in the wine. The wines we tested were between zero and two percent risudual sugar. Fermentation will continue to take place while in the barrel. To determine the pH, I placed a probe into the wine. The probe was connected to an Oakton pH meter. It only took about a minute to get a reading.

To determine the pH, I placed a probe into the wine. The probe was connected to an Oakton pH meter. It only took about a minute to get a reading.