While in the country Georgia, we learned about waxing a qvevri. The inside walls of a qvevri are coated with melted beeswax. This is often done by the qvevri maker after firing; however, winemakers can also wax the interior of the qvevri. I asked qvevri maker Zaliko Bodjadze, in Western Georgia near the village of Makatubani, at what temperature he applies the beeswax to the qvevri. Zaliko smiled and took his hand and touched a qvevri. He can tell the correct temperature by touch. Qvevri maker Remi Kbilashvili in Vardisubani, Kakheti in Eastern Georgia said he waits for the fired qvevri to cool to about 70ºC (158ºF) to apply the wax.

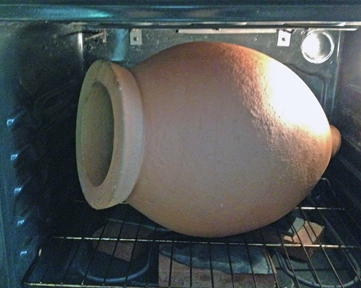

Winemakers that purchases qvevris that have not been waxed should heat the qvevri before waxing. They do this by building a fire in a pot and lowering into the qvevri to heat the inside. We decided that since our qvevri was small, to see if we could heat it in our oven. Making a few minor adjustments, we placed our qvevri into the oven and turned the oven on to 100ºF (38ºC). After a half hour we increased the temperature to 120ºF, then a half hour later to 140ºF and finally to 158ºF (70ºC). We left the qvevri in the oven at this temperature as we melted the beeswax.

Our qvevri was small enough to fit in our oven with a few modifications. We slowly heated the oven to 158ºF (70ºC) and kept the qvevri at that temperature for a couple of hours.

We were told to melt the beeswax in a double broiler until it reaches a temperature between 230ºF to 248ºF (110ºC – 120ºC). It started to melt easily, but we could not get the temperature above 190ºF (88ºC). So we poured the wax directly into a pan and quickly heated it to 248ºF (120ºC). We took the qvevri out of the oven. I held the qvevri while Kathy used a paint brush to coat the interior with the hot beeswax. The paintbrush worked well and it looked like the walls of the qvevri were absorbing the beeswax. I began coating the inside walls as Kathy found a flashlight. It can be dark inside the qvevri and we wanted to make sure we did not miss any of the interior surface. We were finished in a few minutes. Kathy took the extra beeswax and poured it into a wine glass that she placed a wick into. Now we have a beeswax candle in a wine glass.

Melted beeswax approaching 230ºF to 248ºF (110ºC – 120ºC), At 230ºF the melted wax becomes translucent.

Why did we wax the interior of the qvevri? New qvevris are highly porous and if not waxed, there is a chance that wine could leak out or water from the ground could seep in. By waxing the interior, the beeswax acts as a sealer for the porous walls.

We used a good quality beeswax. Kathy’s brother, Richard Linck, has an apiary in Marcellus, New York. The honey he collects is excellent and we made mead one year from his honey. We used beeswax from his bees to coat our qvevri.

Some of the qvevri interior is coated with beeswax that is pooling at the bottom of the qvevri. We used the beeswax in the bottom to coat the interior that we missed.

The experience was fun. It was also humbling. We noted that for thousands of years, winemakers in Georgia have coated the insides of qvevris with beeswax. Being able to experience a part of ancient winemaking technology was a great learning opportunity.

Cheers,

Terry

Bom dia, Muito bom a reportagem que vocês fizeram, pergunto, coloca-se cera de abelha só uma vez, ou coloca todas as vezes que for vinificar.

Att, Emilio Melo,

Brasil, Piauí, Teresina.

Emilio, I asked this question to many qvevri winemakers. The answers ranged from every vintage to only once. The most common answer was once every twenty years.